The VIS-G20 combines economy and ease of use of the control for regulating the viscosity of the ink. The viscosity measurement is done thanks to a vibration sensor, and simpler interface allows operators to edit more easily.

APPLICATIONS Rotogravure / Flexo / coupling / Reprint / Varnishes

The VIS-G20 is a system for the regulation of the viscosity of the solvent-based inks. The measurement of the viscosity takes place thanks to a vibration sensor immersed in the liquid to be analyzed, without moving parts.

It, in series with the flow, emits a frequency that in contact with the liquid is changed, may alternatively also be installed in derivation to the ink flow.

From the analysis extrapolates the viscosity in seconds (cup ZAHN, FORD, …) and by the correction valve maintains the management based on the reference set. The cleaning of the viscometer performed at the end of work, at the same time washing the inking circuit.

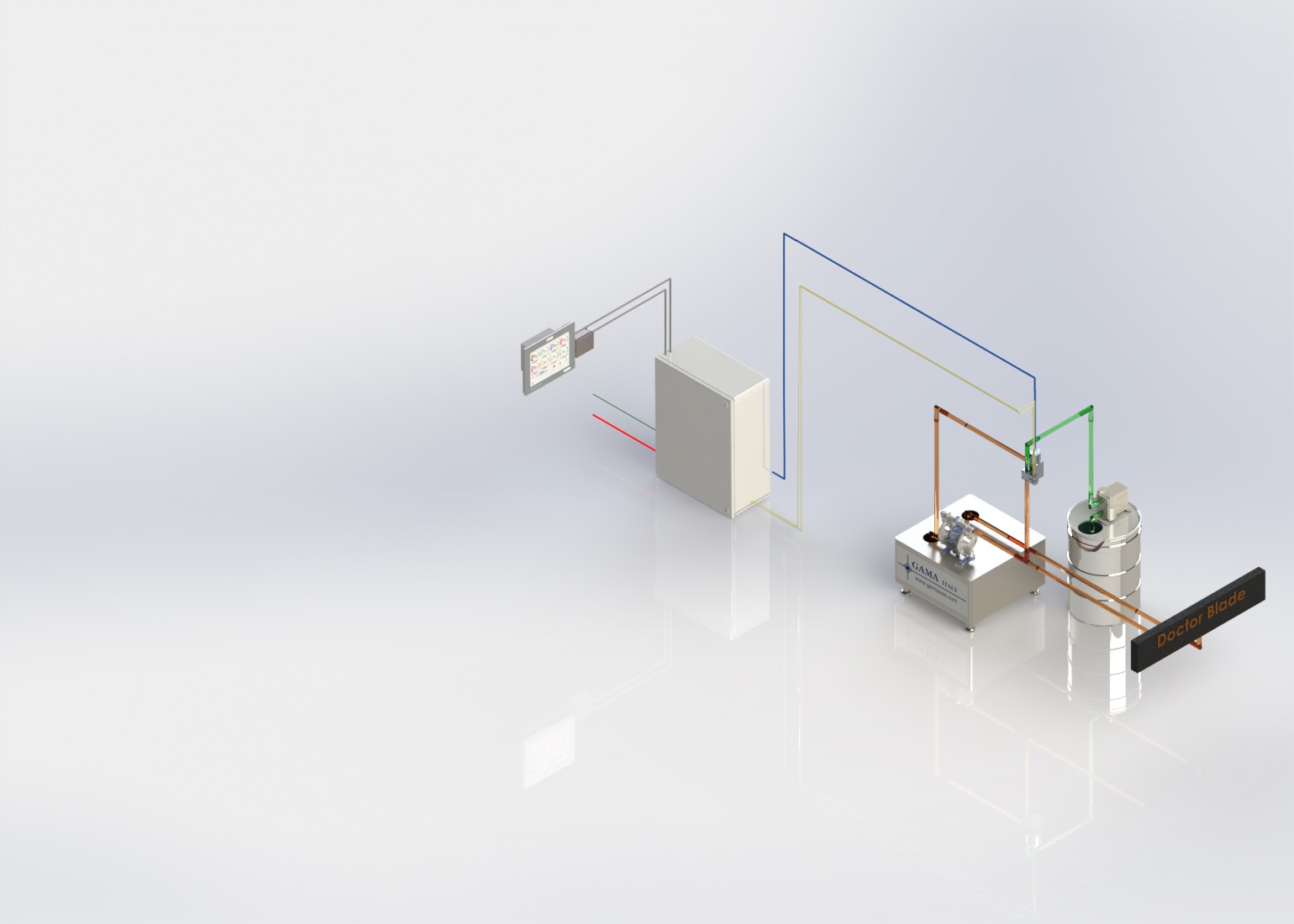

3D application viscometer mounted in derivation, with Gama washing of the viscosimeter.

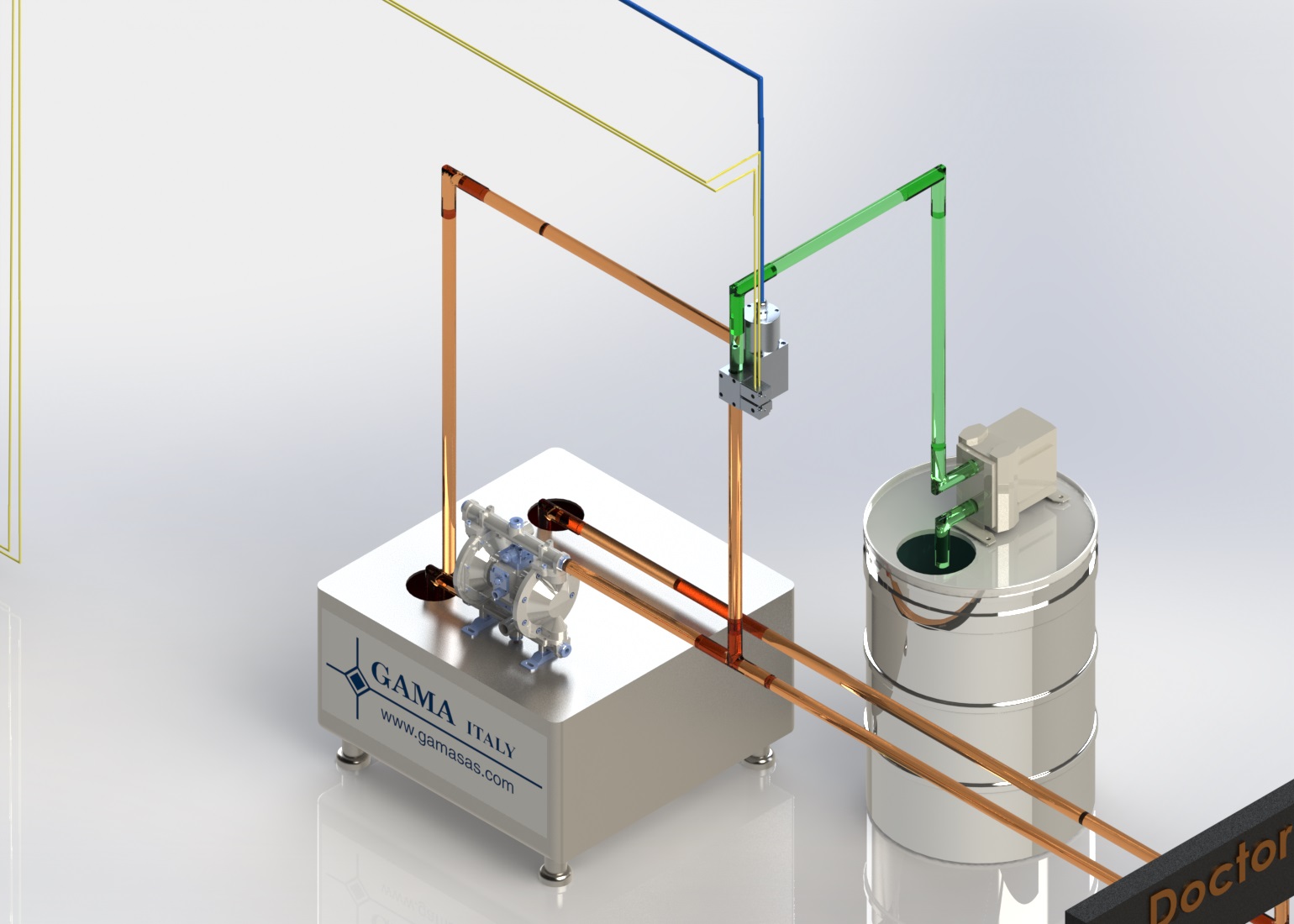

Detail 3D application viscometer mounted in derivation, with Gama washing of the viscosimeter.