The tool to manage and control ink consumption during the printing process.

APPLICATIONS Rotogravure / Flexographic Printing / Lamination / Inks / Cold Seal / Adhesives / Glues / Varnishes / Lacquers

Innovative e indispensable

Innovative because the printing industry can finally rely on a tool based on microprocessor technology, designed to provide data on the use of a key raw material: ink.

Indispensable because it allows you to uncover—that is, to know and manage—the actual production costs related to ink consumption per job, per day, per month, and per year.

With the CCSone, it is possible to record actual ink usage and subsequently compare it, for example, with the estimated consumption for a specific project/job.

The CCSone also provides safety alerts, such as “low ink level” notifications in the container. This helps prevent not only the interruption of ongoing print jobs but also the generation of unusable printed waste due to ink shortages.

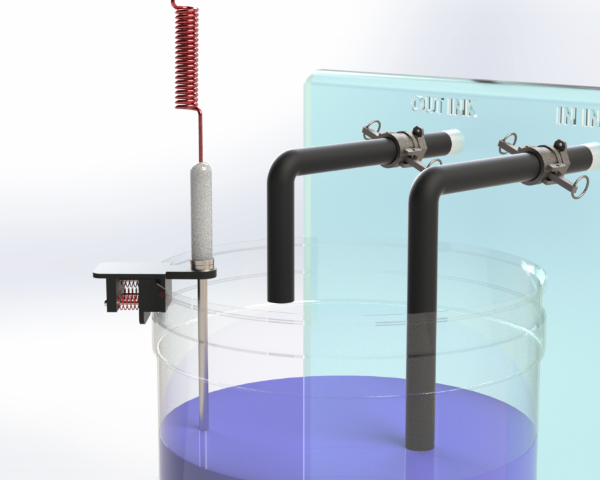

Bucket Lid Application

Bucket Edge Application