The step control print REG-G40-PAS shows the format of the print.

APPLICATIONS Rotogravure / Flexo / coupling / Reprint / Marking Unit / rewinders / Slitter

Basically you install a sensor on a crazy roller cam (just one screw) so that it provides a boost for each lap, and another sensor to provide pulse synchronized with the press. On a machine that uses printed material you synchronize on a brand of cutting free band.

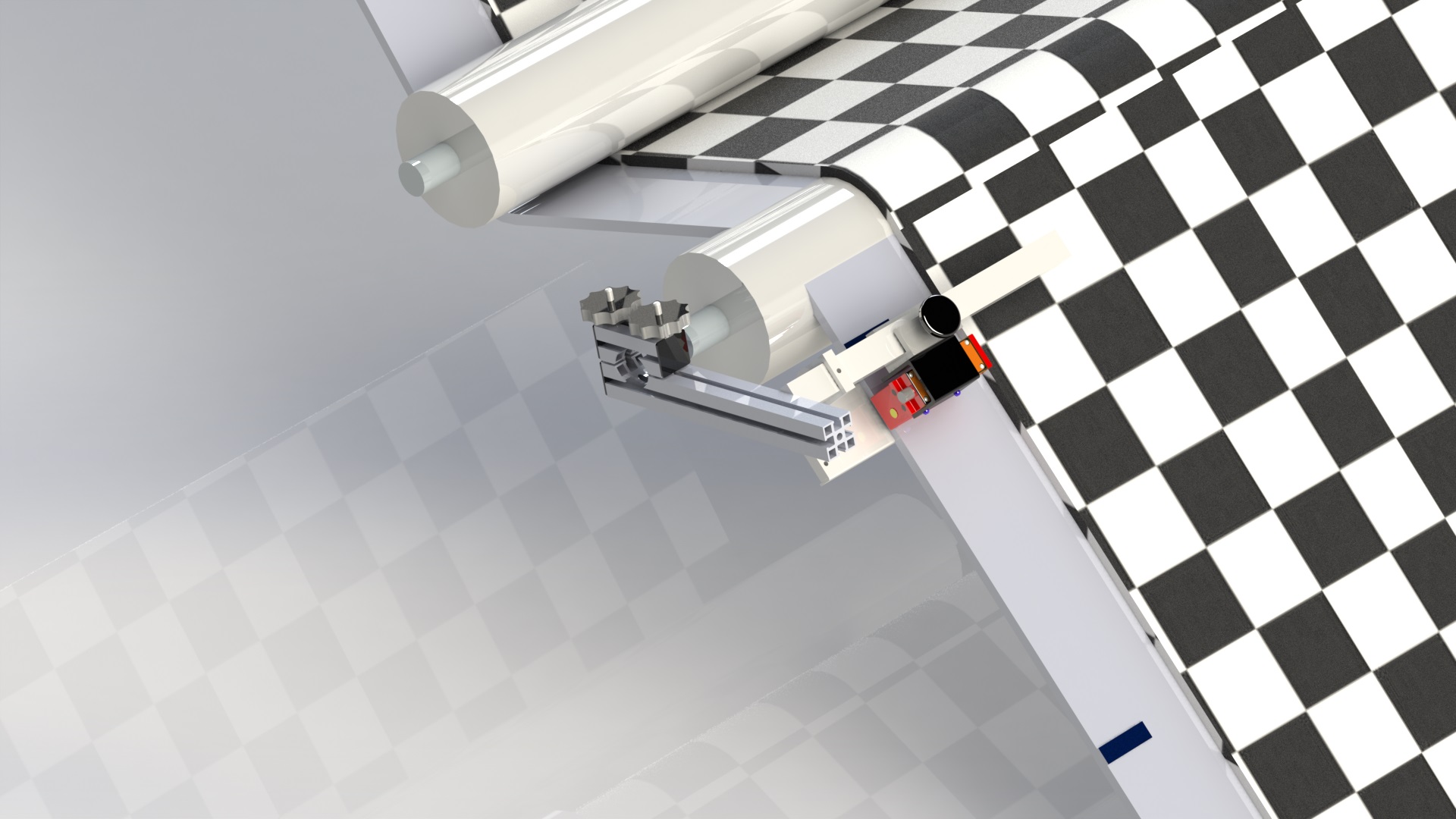

General application of Step Control Head Detail

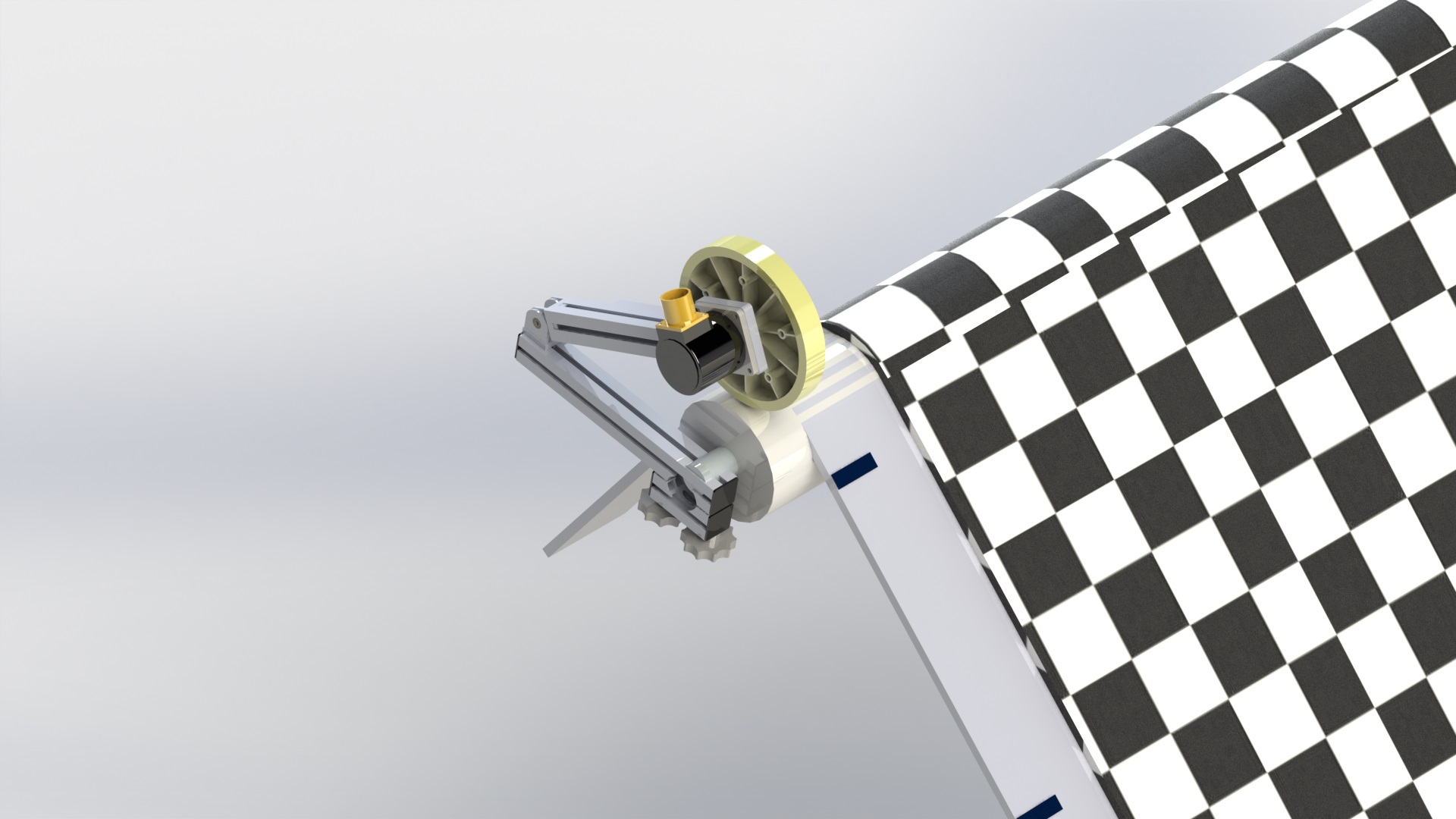

General application of Step Control Detail Encoder