II register control REG-G45-VL is designed to manage the printing register control on rotogravure.

APPLICATIONS

The REG-G45-VLT is the latest longitudinal and transversal register control, which makes use of the new technologies available on the market. The use of microcontroller monitored by a supervisor, improves the characteristics of the machine. In order to adjust the machine to the future requirements, it will not be necessary to modify the existing system, in fact it just needs to update the software.

The operator makes use of the video touch screen or of the membrane keyboard. By means of several windows on the high-resolution monitor, it visualises the parameters of the setting out, as well as the parameters for each printing element. Furthermore it verifies the reading of each colour on a simulator of a digital oscilloscope.

The REG-G45-VLT is composed by peripheral intelligent units with a microprocessor for the control of colour register. Each unit receives the information from the parts of revelation installed on the rotary press, and to each format it supplies simultaneously the orders of correction of the register. It conforms on dynamic situations, reducing wastes due to acceleration, change of bobbin or error in the progressive scale of cylinders.

Encoder Application

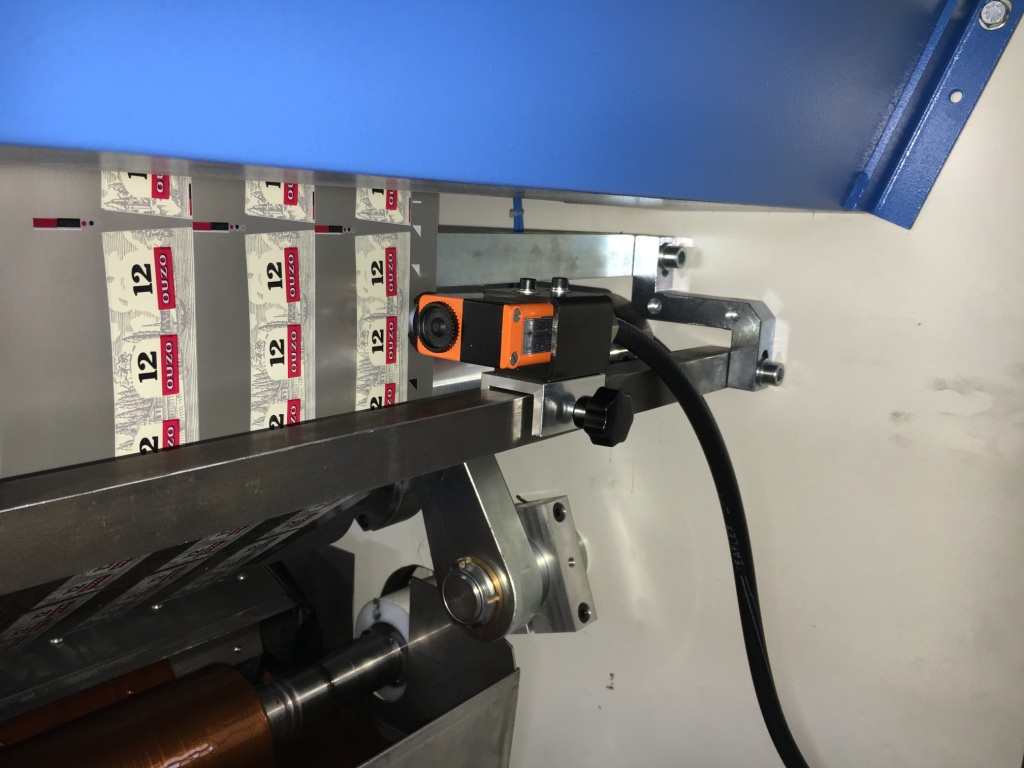

Scanning Head Application